In collaboration with the U.S. Department of Energy’s Oak Ridge National Laboratory in Tennessee, the University of Maine will commence a bio-based 3D printing program that could prove useful in revitalizing Maine’s forest products industry through finding new uses for wood products.

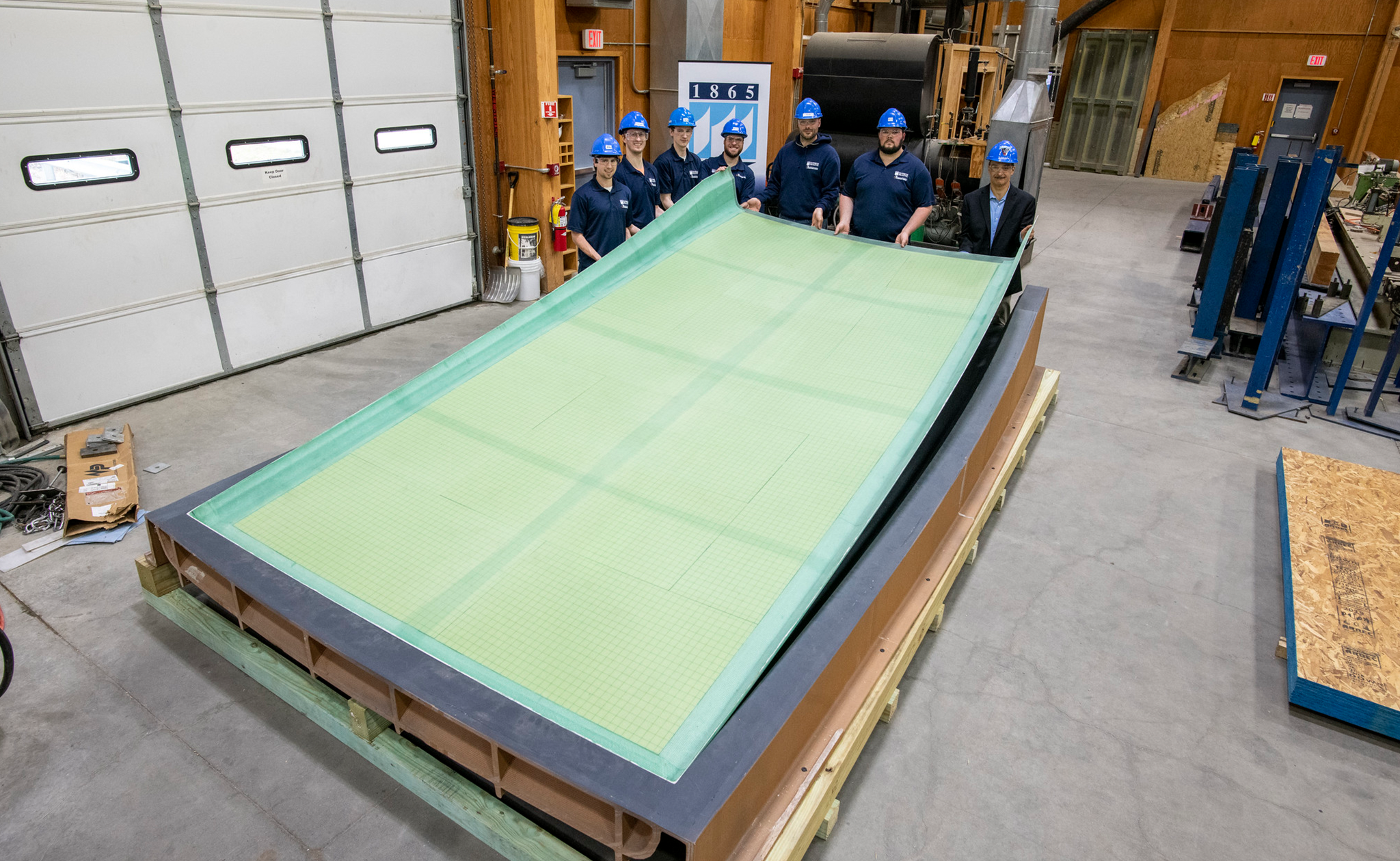

One of the first uses of the printer will be to print a boat mold for boat builders to use. The substance used in the process will be a wood-based plastic developed at the University of Maine.

“The material is nanocellulose, basically a tree ground up to its nano structure,” said Dr. Habib Dagher, founding executive director of UMaine’s Advanced Structures and Composites Center. “These materials have properties similar to metals; we are taking those and putting them in bioplastics so we can make very strong plastics that we can make almost anything with.”

UMaine and Oak Ridge will receive $20 million in federal funds for the program and hope to build it to apply to large-scale applications. The funding will be split equally between the two facilities; UMaine will draw on Oak Ridge’s expertise in 3D printing, and Oak Ridge will learn from UMaine’s composites center and learn about the cellulose fiber.

“Maine is the most forested state in the United States,” Senator Angus King said. “So we’re sitting on a gold mine of fiber and the question is how do we utilize it, how do we create value, how do we create jobs, and this is an entirely new use.”

The printer will be installed on campus sometime in October.